- #Marsurf ps1 explorer software construction software#

- #Marsurf ps1 explorer software construction password#

- #Marsurf ps1 explorer software construction iso#

- #Marsurf ps1 explorer software construction Bluetooth#

#Marsurf ps1 explorer software construction software#

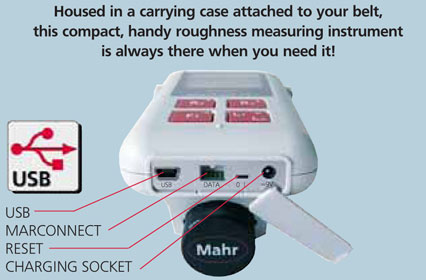

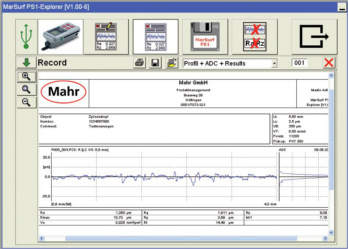

The essential functions of the Software "MarSurf PS1/M Explorer" are to secure and document your measuring results and profiles. Software "MarSurf PS1/M 300 Explorer" for mobile roughness devices You can select your desired drive unit from a list.

#Marsurf ps1 explorer software construction Bluetooth#

NEW: cable-free connection between evaluation unit and drive unitĪ further advantage of the Bluetooth technology:Ĭonnection of several drive units to one evaluation unit. Read the correct results in a poorly lit atmosphere The evaluation unit stand in a "safe place" and delivers exact results without influence from the ambient conditionsĪ large, illuminated color display to read the parameters and the profiles so that you can: The measurement can be started at the evaluation unit MarSurf M 300 or at the drive unit Marsurf RD 18.

Especially with large, cumberson parts, the application engineer can work directly at the measuring site. Up to 4 m distance between evaluation unit and drive unit enable high flexibility for you to conduct your measurements.

#Marsurf ps1 explorer software construction password#

Locking and/or password protection for instrument settings.Integrated memory for up to 40,000 results and 30 profiles.Output of date and/or time of the measurements.Printing of R-profile (ISO/ASME/JIS), P-profile (MOTIF), material ratio curve, measuring record.Tolerance monitoring in display and measuring record.Parameters as per DIN/ISO/SEP: Ra, Rq, Rz, Rmax, Rp, Rt, R3z, Rk, Rvk, Rpk, Rr1, Mr2, Rmr, RSm, RPc.

#Marsurf ps1 explorer software construction iso#

Even here, Mahr shows that its metrology is up to date with modern needs. The cable-free Bluetooth connection between evaluation unit and drive unit is unique in roughness metrology. Over time, we have succeeded in perfecting the stylus method which is now widespread throughout the world. This is where Mahr's core expertise comes in, as demonstrated by the company's numerous innovation and patented solutions.

The interplay between the stylus, drive and measuring setup plays a key role in influencing the quality of surface measurement tasks. For decades, Mahr has been a worldwide pioneer in this area, as demonstrated by the company's numerous innovations and patented solutions in the field of roughness metrology. Measurement and evaluation have become considerably easier. Today, computer-aided measuring instruments provide objective data. Now however, we live in an age of exchangeable parts, fits and internationalization, where subjective tests like this are no longer adequate. A practiced eye can detect features in the µm range, and even the much maligned thumbnail test delivered perfectly acceptable results. But how can surfaces be tested? At the start of the 20th Century, experts still had to test by eye and touch. Wherever surface structures influence the function, processing or appearance of components or products, careful testing is essential. PRODUCTION-RELATED SURFACE ROUGHNESS MEASURING

0 kommentar(er)

0 kommentar(er)